Table of Contents

Report

Author(s):

- Anna Simons

- Jan Latko

- José Hugo Valiente Saltos

- Margot Gutscoven

- Raymond Quinn

Acknowledgement

The Team would like to start by thanking the teachers first of all for giving us the opportunity to participate in this project, but also for helping us with it.

Glossary

<WRAP box 300px>

| Abbreviation | Description |

|---|---|

| AC | Alternating Current |

| DC | Direct Current |

| EMC | Electromagnetic Compatibility |

| EPS | European Project Semester |

| EU | European Union |

| ISEP | Instituto Superior de Engenharia do Porto |

| LCA | Life Cycle Assessment |

| LVD | Low Voltage Directive |

| MDF | Medium Density Fibreboard |

| NREL | National Renewable Energy Laboratory |

| PVC | Polyvinyl Chloride |

| RACI | Responsible, Accountable, Consulted and Informed |

| RAM | Responsibility Assignment Matrix |

| ROHS | Restriction of Hazardous Substances in Electrical and Electronic Equipment |

| SA | Société Anonyme/Sociedad Anónima |

| SMART | Specific, Measurable, Achievable, Realistic and Timed |

| SOSM | Self-Oriented Solar Mirror |

| SWOT | Strengths, Weaknesses, Opportunities and Threats |

| US | United States |

| USB | Universal Serial Bus |

| WBS | Work Breakdown Structure |

</WRAP>

1. Introduction

1.1 Presentation

Within the European Project Semester (EPS), the authors were Team three (see Fig. 1), or better known as Team Tree. The motto of the Team was planting a tree, the Team planned to “plant a tree”, built a project, and make it grow. Eventually, the Team hoped to profit from the fruit, taking the knowledge and experience gained to apply it in the future.

The Team consisted five students, all with a different background of education and all from other countries. These five students spended the spring semester of 2017 in Porto working at ISEP. The Team consists of:

- Margot Gutscoven (Civil Engineering Technology) of Belgium

- Jan Latko (Computer Science) of Poland,

- Raymond Quinn (Electrical Power Engineering) of Scotland,

- José Hugo Valiente Saltos (Mechanical Engineering) of Spain and

- Anna Simons (Industrial Management) of Finland.

The Team would draw on this diverse range of knowledge and experience to try and deliver a successful project. The aim of this report was to provide information on the all of the different challenges and considerations related to the project and to show how the Team has tackled these issues.

<WRAP centeralign>

</WRAP>

1.2 Motivation

The Team have spend their semester building a Self-Oriented Solar Mirror (SOSM). The solar mirror is a simple way to harness solar energy and to transform it into energy that can be used daily. Raw materials are overused and new sources of energy are needed. This was why the Team were drawn to the solar mirror project, this way the Team could contribute to a better and greener Earth. People are thinking more and more in an environmental way and it is necessary as engineers to facilitate this.

The Team hoped the EPS program would help them to become better engineers and give them experience of working in a multidisciplinary international Team. The Team hoped to develop English skills but also learn something about different fields of engineering. The members could apply their own knowledge but also learn from the others. It was also possible to learn about different cultures, how to interact with people from different parts of Europe and see how they differ, but also see the similarities.

1.3 Problem

The goal of this project was to develop a Self-Oriented Solar Mirror (SOSM). The purpose of the mirror is to heat a certain object or to light up a room. The mirror must track the movement of the Sun and reflect the sunlight onto a predefined area. The creation of the sun tracking system was one of the main challenges for the Team. First of all either to track the sun with or without sensors. If there had been decided to make a solar mirror without sensors, and put the path of the sun in the software. This would have meant that their had to be a way to input the address where the mirror is used and so leaded to more challenges.

Also designing the mechanical part was a big challenge. How to make the solar mirror move in two axes, what materials should we use for this and how to make sure that all the materials fit into our design. The SOSM is also a device that has to be outside, therefore it has to be robust against weither changes.

1.4 Objectives

The objectives of this project is to design a SOSM that detects the Sun by itself with the aid of software that knew the path of the Sun. The consumer would need to do a setup in the beginning defining on which point the mirror has to be focused. The Team could contribute to a greener planet through the development of this product, therefore the product has to be sustainable.

Another objective was to cooperate well in a Team and learn to work in a multicultural environment. The deadlines were all to be taken seriously and be respected. The team members should try to listen to listen to each other and help each other. Also arguments had to be resolved as soon as possible.

1.5 Requirements

This project is part of the EPS at Instituto Superior de Engenharia do Porto (ISEP) 2017. The EPS is a program that brings students together from all over Europe. The program is designed mainly for engineering students, but others can participate as well. The students were divided into small groups of five students, preferably from different countries, and with different fields of study. Every group had to choose a different project to work on during the semester. The students had to attend support classes on ethics, sustainability, marketing and project management. The students were supported by a panel of supervisors that consists of teachers from various fields. There were certain requirements that the project should fulfil.

These requirements are:

- Use low cost hardware solutions.

- Use open source software.

- Adopt the international system of units (NIST).

- Comply with the 2006/42/CE 2006-05-17; 2004/108/EC 2004-12-15, 2014/35/EU 2016-04-20, 2014/53/EU 2014-04-16 and ROHS EU Directives.

- Stay under the budget of 100.00 €.

1.6 Functional Tests

In order to evaluate the project, certain functional tests have to be done. This way the product can be improved where necessary. Some functional tests are:

- Test if the solar mirror tracks the Sun correctly.

- Test if the sunlight is reflected at the correct angle.

- Test if the materials used can withstand heat.

- Test if the area that needs to be heated/illuminated, is heated/illuminated.

1.7 Project Planning

Table 2 contains the different tasks to perform, as well as the person responsible for it.

<WRAP centeralign>

</WRAP>

<WRAP box center centeralign 600px>

| Task | Responsible |

|---|---|

| Initial Planning | |

| Task Identification and Allocation | Margot |

| Gant Chartt | José |

| Technical Research | Jan |

| Market Research | Anna |

| Initial Budget Planning | Raymond |

| Purpose Definition | All |

| Specific Planning | |

| System Diagrams | Jan and Raymond |

| Structural Drafts | José |

| Design | José |

| List of Materials and Budget Re-planning | Raymond |

| Interim | |

| Project Management | Anna |

| Eco-Efficiencey Measures for Sustainability | José |

| Ethical and Deontological Concerns | Jan |

| Upload Interim Report and Presentation | Anna and Margot |

| Interim presentation | Anna and Margot |

| Upload Refined Interim Report | Anna and Margot |

| Complete List of Materials | Raymond |

| Construction | |

| Construction Hardware | José and Raymond |

| Construction Software | Jan |

| Testing | |

| Product Testing and Corrections | Jan, José and Raymond |

| Upload Functional Test Results | Jan, José and Raymond |

| Final | |

| Upload the Final Report and Presentation | Anna |

| Upload the Movie, Poster, Manual and Leaflet | Margot |

| Final Presentation, Individual Discussion and Assessment | Jan, José, Margot and Raymond |

| Upload the Wiki with all Correction Suggestions | Anna |

| Hand in a CD with all the Corrected Deliverables | Margot |

| Hand in one Printed Exemplar of the Corrected Report | Anna |

| Hand in the Prototype and User Manual to the Client | Margot |

</WRAP>

1.8 Report Structure

The report is divided into eight chapters, which include different subsections. The different chapters are detailed at Table 3.

<WRAP centeralign>

</WRAP>

<WRAP box center centeralign 800px>

| Chapter | Title | Description |

|---|---|---|

| 1 | Introduction | Short description of what the project is about, the objectives and requirements |

| 2 | State of art | Technological and market research. How the mirror has to be built, which materials are best to use, how software will be used etc. |

| 3 | Project management | The task and time allocation. How the tasks are divided and when they must be completed to be able to finish the task in time. |

| 4 | Marketing plan | Who is going to buy the product. |

| 5 | Eco-efficiency measures for sustainability | What the Team have done to make the project eco-efficient and the measures the Team have taken to make it sustainable. |

| 6 | Ethical and deontological concerns | The ethical concerns regarding the solar mirror. |

| 7 | Project development | How the project was developed, the problems encountered and how they have been tackled. |

| 8 | Conclusions | A brief summation of the main conclusions of the project. |

</WRAP>

2. State of the Art

2.1 Introduction

In the State of the art, the technologies that are already on the market are going to be discussed; this topic refers to the highest level of general development, as of a device, technique, or scientific field achieved at a particular time. This is done to get ideas and maybe add them to our product. Especially the different purposes of the solar mirror are going to be discussed. This was done to find first of all, the purpose of these mirror, see where there is a gap in the market and which ideas are not made into reality yet.

A solar mirror is a substrate covered with a reflective coating, this way it can reflect the sunlight to a certain point. The substrate can be flat, but can also have a parabolic form. The goal of the SOSM is to reflect the sunlight and to achieve a significantly higher concentrated reflector factor.

2.2 Purpose

A solar mirror can be used for lots of purposes. Mainly it is used to heat things. The heat can be used directly in homes for warm water, but can also be transformed into electrical energy. Another way to use the solar mirror is to use it for light. The solar mirror could be put a garden and pointed at a window to bring more light into a room. In this chapter the different purposes of the solar mirror are going to be explained.

2.2.1 Heliostat

2.2.1.1 Purpose

The heliostat is a mirror targeted mainly at small scale or personal use. It can light up rooms, work areas, desks, small gardens, etc. depending on the size of the mirror. The mirror is universal, not task specific, but focused on providing light rather than heat or electrical energy [1]. Fig. 2 illustrates a room before and after reflecting sunlight with a mirror. It shows that such a device could make a room significantly brighter.

<WRAP centeralign>

</WRAP>

2.2.1.2 Technology

For the technology of the solar mirror different parts will be needed:

- Sensors or a Real Time Clock (RTC)

- Controllers

- Actuators

Sun Tracking

There are two different ways of following the route of the sun, using sensors that redirect the mirror to the sun or programming the route by prior knowledge of the apparent movement of the sun. In both cases the position of the Sun and of the center of focus is needed. The position of the center of focus could be either set mechanically with a pointer or input digitally, for this it two angles and optionally a distance is needed. Some kind of positioning device could also be used as a target for the mirror.

For the position of the Sun two approaches could be considered. First is setting a date (day, month and year), time and geographical location and calculating the Sun position from that data. According to the authors of Solar Position Algorithm for Solar Radiation Applications[3] most of such algorithms do not achieve uncertainty smaller than 0.01 °, while their own algorithm is much more accurate. The advantage of this approach is that it does not require any additional sensors. The disadvantage is that it works only with sunlight and does not take into account light reflections, artificial sources of light nor objects that can eclipse the Sun, like trees and buildings.

The second approach needs several light sensors. What makes the case even more complex is that the mirror has to reflect the light in a specific direction rather than just turn itself towards the Sun. One way to achieve this would be not to place a Sun tracking sensor together with the mirror, but move them separately with the mirror position depending on the position of Sun tracker[4], the mirror’s normal should be the bisector of the angle between the Sun tracker and the focus direction. This solution involves much more complicated mechanics, but simplifies electronics and computation and involves components that might be easier to find.

Another way is to build a sensor that would tell exactly where the light is. There are different ways to do this. First of all several light intensity sensors could be used to approximate where the light intensity is at its strongest. An alternative option is using a box with a hole and detecting where the Sun spot is on the bottom of the box (shown in Fig. 3) [5]. There might be some sensors that would provide this functionality out of the box, nevertheless these are not easily available and may be more expensive.

<WRAP centeralign>

</WRAP>

Controller

The controller receives the input of the sensors, processes it into actions that are send to the actuators. The microcontroller board is necessary for the angles calculation. Unless a movable sensor with some mechanical way of moving a mirror and setting the target is present, in which case only a simple electronic circuit can be used as a controller.

Actuators

The mirror needs to be rotated in two axes, therefore two motors, some construction and most probably some angle monitoring are needed.

2.2.1.3 Budget

To build a prototype of a device that tracks the sun to make proof of concept of our project, it will need an Arduino controller, an arduino controller costs about 20.00-25.00 €, but some alternatives can be found for 10.00-15.00 €. Simple photocells will be needed if there had been decided to work wit light sensors, light sensors can be bought for about 1.00 €. Quad photodiodes cost about 5.00-6.00 €. Direct Current (DC) motors can be bought from 2.00 € (depending on size and torque). A Display can be found for about 10.00 € or less and a 4-digit display costs 2.00 €. The device’s cost depends mostly on the price of light sensors and mechanical components and materials [6].

2.2.1.4 Market research

The Sunflower is shown in Fig. 3.

<WRAP centeralign>

</WRAP>

“Sunflower” is a heliostat for home use [8]. It costs 299.00 dollars, but it is not available for the moment, because it is sold out. Its price could be considered affordable. Other heliostats on the market are larger and significantly more expensive, they cost around 1 840.00 € [9]. There are not so many heliostats easily available on the market, H1 Heliostat [10] that costs 2 000.00 € is the only one that can be easily found on the internet. That means that with good marketing there is a possibility to replace currently unavailable Sunflower and create an affordable heliostat for home use. Price of the device should therefore be less than 275.00 € for a small size mirror or more for a larger one.

2.2.2 Cooking mirror

2.2.2.1 Purpose

A solar cooker could be used for outdoor cooking and possibly grilling. Such a device could also be used to heat something up or keep it warm. As such a function does not exactly need a solar tracking system it might be good to add some functionality such as temperature monitoring or a timer. On the other hand if the cooking or heating takes a long time, self-control would be a useful feature.

2.2.2.2 Technology

There are three possible ways to heat food [11]. First of all, the easiest way is to reflect the sunlight by mirrors to an area, the cooking area, for example Fig 5 a. The only problem with this method is that it can provide temperatures from 65 °C, which is a good baking temperature to 400 °C on a sunny day, which is a high enough temperature to melt metal. A second possibility is to concentrate the sunlight onto a receiver, for example a cooking pan or pot. To maximize the heat absorption, it would be best to use a matte black pan or pot (Fig 5 b). A third way would be to trap the heat, in this way one should make sure that the isolate the air, this would ensure that on cold and windy days, one could also use the solar mirror. A windshield would also prevent the food from cooling down(Fig 5 c).

<WRAP centeralign>

</WRAP>

As the SOSM only needs to rotate towards the Sun the control system would not be complicated. A one or two axis construction and a pair of sensors for each axis would be enough. Motors are triggered when there is a difference between the intensity of light received by sensors of a pair. Then the mirror should be rotated towards the brighter Sun. Additional functions might involve a controller and additional sensors for temperature monitoring (a thermometer) and time measuring [15].

2.2.2.3 Budget

A sensor might be based on 2 to 4 light sensors for 1.00 € or one quad photodiode for 5.00-6.00 € and the device needs 1 or 2 motors (depending on the size 2.00-10.00 €). A controller costs around 10.00-25.00 €. Nevertheless a cooker might involve more expensive materials as it needs to handle high temperatures.

2.2.2.4 Market research

The solar cooker could be a suitable device for garden parties or barbecues and would suit a recent trend off “being ecologic”. Such a device has to be rather big, so its mobility would be limited. Nevertheless it could be easily transported with a car. There are several examples of solar cookers and ovens on the market. None of them are self-oriented nor have any additional digital functions. Therefore there is a possibility to build a device that would be more convenient to use, because of the automation and possibility to add some helper functions, dor example putting a timer on the solar mirror and when the food is done, the device would turn away from the sun. The prices of the existing ones vary from 45.00 € for a rather simple and small version of solar cooker to 275.00-370.00 € for bigger and more advanced solar ovens [16]. The first price is low, but the cooker is also very simple, therefore our device could be much more expensive. Its price could even be higher, as it would provide much more functionality.

2.2.3 Agricultural solar mirror

2.2.3.1 Purpose

Agricultural solar mirrors are used for growing plants, vegetables, tomatoes and so on. They can also be used to make plants grow larger, longer and more plentiful and better [17]. Fig. 6 shows an example of a solar mirror that is placed under a tree. This way the tree leaves that are normally always in the shadow, because there covered by the upper leaves, can last longer. This have been done with and without a rotating disk [18].

<WRAP centeralign>

</WRAP>

Another application of the solar mirror is to dry fruits and vegetables. It is very important to dehydrate fruit and vegetables, this ensures that they can be preserved longer and add value to the products by controlling the moisturising [20].

2.2.3.2 Market Research

There is a farm in the South Australian desert where they grow tomatoes by using just sunlight and seawater. They turn seawater and sunlight into energy and water, and use sustainability sourced carbon dioxide and nutrients to maximize the growth. After the seawater arrives at the farm, it is desalinated at an on-site, solar-powered plant that turns it into fresh, plant-ready water by 'scrubbing' the salt out of it. They have a field of mirrors that focus the Sun´s rays onto a fixed tower, where it powers a generator to create electricity. In this case, there is 180 000 tomato plants and 23 000 mirrors, and it cost 200 million US dollars to build. So in this case the mirror could be used to both desalinate the water for the plants and to make the plants grow [21].

2.2.4 Desalination

2.2.4.1 Purpose

Desalination signifies the removal of salt and other minerals from a substance. These minerals can be bad for human consumption, but also for agricultural purposes; therefore it is best to remove them. In dryer countries desalination is particularly relevant. It is a fact that regions where the clean water source is scarce, have plenty of solar radiation. This is why it would be very advantageous to use solar radiation for the desalination of water; Nevertheless this requires large amounts of energy. Using solar radiation would be a way to produce emission free renewable energy. The solar radiation can be converted into electrical energy and used for the condensation of the water or it can be used directly to condensate water.

2.2.4.2 Technology

Most technologies to desalinate water involve the evaporation of water and after condensing the vapour back to its liquid state [22]. Commonly vacuum distillation is used, where the pressure is lowered so a lower temperature is needed to evaporate the water.

2.2.4.3 Market Research

The demand for water desalination products increases by 9.30 % per year. The worldwide water distillation industry is worth about 8.60 billion dolars. Veolia Environment S.A., Acciona S.A. and General Electric Co. are some of the key players in the water market with a focus on the distillation industry. They cover Saudi Arabia, the United Arab Emirates and the United States of America [23].

The desalination of seawater is, in general, more costly than the desalination water from rivers or ground water. Currently, 1 % of the population depends on the desalination of water. Water is the major necessity of life, a lack of it can affect agriculture and lead to thirst and famine. Nevertheless this seems like a suitable solution, economically and environmental it has appeared to be not. Although it is beneficial for solving the drought problems, it is recommended to find other solutions to protect the economy and the ocean life.

How would this affect the economy? For example, for the last decade people are suffering from drought in California affection around about 64 million people, due to changes in the rainfall patterns. Because of the drought the agriculture has been seriously affected. Which has led to a weaker economy, as agriculture is the main source of revenue. Desalination could be a solution, nevertheless there are flaws. Building the desalination installation will cost up to 1 billion dollars or 0.90 billion €, which is too high for a community [24].

In this project a small desalination for home use could be produced. The market target will be third world countries, where they do not have clean water coming out of the tap, or just can go the store to buy some. The people who need the water distiller are naturally not capable of buying the distiller themselves, that is why first of all charity organizations are the main target group. Charities such as WaterAid, WellFound, WorldVision, Water.org would be perfect targets for this project [25].

2.2.5 Water heating

2.2.5.1 Purpose

One solution could be to use the mirror for water heating. A lot of houses already have a solar water heater on their roof. The mirror could help to heat it even more and gain even more energy to heat the water. A solar water system includes solar collectors and storage tanks. When adding the mirror more solar collectors should be added because the light will come from another point. Fig. 6 shown a picture of a solar water heater.

<WRAP centeralign>

</WRAP>

2.2.5.2 Technology

There are two kinds of solar water heaters, the active kind and the passive kind. The active kind has circulation pumps and controls and the passive kind does not. They both have two possibilities. In the first case normal water can be pumped around, this can only be used in climates where it does not freeze that much, otherwise the water is going to freeze and the system will be blocked. In the second case the pump circulates a non-freezing fluid through the system, this case is more expensive, but certainly necessary in cold climates [27].

The water in the solar collectors is heated and afterwards sent to the storage. The heat can be stored in a tank or in the masonry mass of a radiant slab system. The role of the mirror will be to heat the collectors more than they heat with only the Sun.

2.2.5.3 Market Research

The challenge here would be to make the water heater as efficient as possible so that people will save more money than they will use in paying for the energy. This also means that the product will have to be sustainable, it has to have a long lifespan, so it will live long enough to make profit out of it.

2.2.6 Solar Energy Production

2.2.6.1 Purpose

The purpose of using solar mirrors in electricity production is to harness the power of the Sun. Most solar power plants use a vast field of hundreds to thousands of heliostats which reflect the sunlight up to a tower situated in the centre of the field. The mirrors focus the sunlight on one area of the tower and this focused light is many times more intense than regular sunlight (see Fig. 8). One plant in California can power over 75 000 homes [28].

<WRAP centeralign>

</WRAP>

2.2.6.2 Technology

Some power plants use heliostats with light and heat sensors which can track where the Sun is in the sky in order to be in the optimal position to reflect the sunlight to the desired area. Other plants use a timed system where pre-recorded data about the Sun’s position in the sky is used to position the mirrors, however the mirror’s position can be adjusted by an engineer from a central control room in order to get as much energy from the Sun as possible [29].

At the top of the tower are tanks containing oil. This oil is heated by the reflected sunlight and can reach 500 °C and more. This heated oil is used to turn water into steam which drives a steam turbine to produce electricity much in the same way as a conventional power plant using a non renewable fuel source. There are also other methods such as storing the heat energy in molten salt which allows the plant to produce electricity even during hours where the Sun has set meaning the plant is operational 24 hours a day. The energy stored in the salt can drive a turbine for up to 15 hours [30].

2.2.6.3 Environmental Concerns

There are a great many environmental concerns when it comes to concentrated solar power plants. Wildlife may need to be displaced in order to build the plant. There are also a great many avian deaths every year. When birds fly into the path of the concentrated light they can be burned and killed. Some plants are also not entirely powered by the sunlight. Many require natural gas to be burned each morning to get the plant started up.

2.2.6.4 Budget and Market Research

Such systems for creating electricity from sunlight are very expensive. The Planta Solar 10 in Spain cost 35 000 000 € to build and can power 6 000 homes day and night [31]. The Ivanpah plant in the Mojave Desert cost 2.20×10^9 $. Building such a system on a small scale does not make sense financially. In terms of competitors there are many commercial power plants already in operation as well as many more planned developments. It is possible that a smaller scale plant would be a viable way to meet the energy needs of a small town in a more environmentally friendly way.

2.3 Conclusion

The advantages and disadvantages of using one of the different purposes for our project are summed up in Table 4.

<WRAP centeralign >

</WRAP> <WRAP box center centeralign 800px>

| Purpose | Advantages | Disadvantage |

|---|---|---|

| Heliostat | It will be possible to make it cheaper than the ones that are already on the market | The difficulty is here to reflect the sun always to the same point, as for example for the solar cooker, the object that needs to be heated will always move together with the mirror |

| Cooking Mirror | It will be possible to make a product that is not on them market yet, by adding gadgets like a timer | The things that need to be cooked, also the things where there need to be cooked in (the pans and pots), are expensive, and out of our budget |

| Agricultural Solar mirror | There are not many devices like this on small scale | The difficulty is here to reflect the sun always to the same point, as for example for the solar cooker, the object that needs to be heated will always move together with the mirror |

| Desalination | It is something new on the market, there are no self-oriented desalination devices | It will be difficult to build the device that desalinate the water |

| It is expensive to build the part to desalinate water | ||

| Water heating | Easy to build, because we don't have to reflect the sunlight to a certain point, the device that would need to be heated will move with the mirror | It will be difficult to build the device that heats the water |

| It makes the project more expensive | ||

| There are already a lot of them on the market | ||

| Solar energy production | Easy to build, because we don't have to reflect the sunlight to a certain point, the device that would need to be heated will move with the mirror | It will be difficult to build the device that conserves the energy |

| It makes the project more expensive | ||

| There are already a lot of them on the market |

</WRAP>

The derived requirements of the SOSM are:

- it has to be able to track the Sun without sensors

- it has to reflect the sunbeams to a certain point, defined by the consumer

Building a solar cooker or a water distiller would take a lot of time and it would be very challenging technically. Therefore it has been decided to focus on the mirror itself, not the object heated/lighted up as creating a Sun tracking system is a challenge on its own and there is not either time or budget to focus on the additional features. The mirror will be for home-use. Whether to use it to bring more light to a room or garden or to heat something is the customer's choice. So the mirror can be used in several ways. The challenge will be to follow the Sun and reflect the radiation to one point.

3. Project Management

3.1 Introduction

Project management is the application of knowledge, skills, tools and techniques to project activities to meet project requirements. Project management is accomplished trough the use of the processes such as: initiating, planning, executing, controlling, and closing [32]. The project Team manages the work of the projects, and the work tipically involves:

- Competing demands for: scope, time, cost, risk, and quality.

- Stakeholders with differing needs and expectations.

- Identified requirements.

3.2 Scope

Project Scope Management includes the processes required to ensure that the project includes all the work required, and only the work required, to complete the project successfully. Scope's Definition involves subdividing the major project deliverables into smaller components to [33]:

- Improve the accuracy of cost, duration, and resource estimates.

- Define a baseline for performance measurement and control.

- Facilitate clear responsibility assignments.

A precise scope definition determines the success of project. Otherwise, the final project costs may increase, due to the project changes, which involves rework and increase project time.

A fundamental tool used for Scope Definition is the Work breakdown structure (WBS). A WBS is a deliverable-oriented grouping of project components that organizes and defines the total scope of the project. Its hierarchical form allows an easy identification of the final elements, also called work packages [34].

For this Self-Oriented Solar Mirror Project, the WBS is shown in Fig. 9.

<WRAP centeralign>

</WRAP>

3.3 Time

Project Time Management includes the processes required to ensure timely completion of the project [35]. These processes are described below:

- Activity definition: This involves identifying and documenting the different activities to be carried out. In this way, it will be possible to produce the different deliverables identified in the WBS.

- Activity sequencing: This involves identifying and documenting interactivity logical relationships. The mandatory dependences are the most important; identify which activities are not possible to start unless another ones have finished, and vice versa.

- Activity duration estimating: This involves taking information on project scope and resources and then developing durations for input to schedules. At the beginning of the project, this may be a difficult task, unless the customer sets some deadlines for some of the work packages.

- Schedule development:This means determining starts and finish dates for projects activities. This is directly related to the activity duration estimating.This means determining starts and finish dates for projects activities. This is directly related to the activity duration estimating.

- Schedule control: This involves the detection of changes in the schedule and the management of the same, in order to ensure that changes are agreed with the contractor.

In order to have this information in a simple and effective way, nowadays a tool called Gantt Chart is used. Of all the information that can be obtained, stands out:

- The duration of a given project, and each of the work packages.

- Know exactly the stage in which this one is located.

- Identify possible delays in lead times.

- The existing connections between the different activities.

- The different expected deadlines.

The Gantt Chart of the project described in this report is shown in Fig. 10 and Fig. 11. In this table all the deliverables are displayed and how long it takes to realize everyone of them. In the second table one will see how much percentage of the each Team members time was divided to these deliverables. As can be seen, the duration of the whole project had to be done between 02.03.17 to 29.06.17.

<WRAP centeralign>

</WRAP>

<WRAP centeralign>

</WRAP>

3.4 Cost

Project Cost Management includes the processes required to ensure that the project is completed within the approved budget. These processes are described below [36]:

- Resources planning: It involves determining what resources are required, and what quantity of each one, to get done all the project activities. There are three main types of resources [37]:

- Human resources: It is important to determine the different human resources available and the assigned workload for each one. This assignment should be done base on the different work packages, and also the strengths and weaknesses of each of the human resources.

- Capital: The capital is essential to be able to carry out each of the different phases of the project. The same will be used to cover the salary of the different human resources, to launch the product to the market, and for the different contingencies that may arise on the fly.

- Material goods: Those assets, whether tangible or intangible, necessary for the achievement of the project.

- Cost estimating: Cost estimates are quantitative assessments of the costs for each resource needed to perform the project activities.

- Cost budgeting: This involves allocating the overall cost estimates to individual activities or work packages to establish a cost baseline. This cost baseline will be used to measure and control cost performance on the project.

- Cost control:The cost control is important to detect the variances of the cost relative the cost baseline. Only then, it is possible to correct or approved changes not included in the same.

Regarding the commented above, Fig. 12 shows the different human resources available, as well as the total work hours and the baseline cost of the same ones. Besides, Fig. 13 shows the total cost of these resources, as well as the baseline cost. These estimates have been taken assuming a work resource price of 10.00 €/h.

<WRAP centeralign>

</WRAP>

<WRAP centeralign>

</WRAP>

A first approach, as shown in Fig. 14, has been made to the material resources needed for performance of the prototype, since it is not known yet exactly what and how many of these are to be used. In this way, the cost baseline estimate can be made.

<WRAP centeralign>

</WRAP>

As mentioned in section 1.5, it is mandatory to stay under the budget of 100.00 €, at least as far as the prototype manufacture is concerned. Nevertheless, looking for the best quality-price relation, the final product may be a bit more expensive.

3.5 Quality

Quality means, at its most basic level, meeting the needs of customers. Project Quality Management includes the processes required to ensure that the project will satisfy the needs for which it was undertaken. There are three key quality management concepts to consider during the project execution [38]:

- Customer satisfaction: It is important that the customer feels the product or service meet their needs, as well as does it with the right quality. Otherwise, the customer will be unsatisfied. In order to avoid this inconvenience, is necessary to consider the following two aspects:

- Product quality: The product must be made of good quality materials, must be pleasing to the eye, and easy to assemble, disassemble and transport.

- Service quality: Once the product has been sold, the consumer must be provided with all the necessary documentation to start the product. In addition, it will be necessary to provide an efficient after-sales service in case of operating problems.

- Prevention over inspection: The Cost of Quality includes money spent during the project to avoid failures, and the money spent after the project because of failures as well. This type of costs are shown in Fig. 15.

<WRAP centeralign>

</WRAP>

- Continuos improvement: Continuous improvement is the ongoing effort to improve the product, in order to deliver the one deemed most convenient.

Those processes required to ensure the meeting of this quality need, are described below [40]:

- Quality planning: This involves identifying which quality standards are relevant to the project and how to satisfy them.

- Quality assurance: Evaluating overall project performance on a regular basis to provide confidence that the project will satisfy the relevant quality standards.

- Quality control: This involves monitoring specific project results to determine if they comply with relevant quality standards, and identifying ways to eliminate causes of unsatisfactory results. For that, the supervisors' reviews and the testing explained section 7.6 are needed.

3.6 Human resource

Project human resource management includes the processes required to make the most effective use of the people involved with the project. These processes are described below [41]:

- Organizational planning: This involves identifying, documenting, and assigning project roles (who does what) and responsibilities (who decides what). In order to assign both, a Responsibility Assignment Matrix (RAM) is widely used. The most typically used is called Responsible, Accountable, Consulted and Informed (RACI) matrix. The description of each of the roles is as follows:

- Responsible (R): Individual(s) who actually complete the task.

- Accountable (A): Individual who is ultimately answerable for the activity or decision. Only one “A” can be assigned to an action.

- Consulted (C): Individual(s), typically subject matter experts, to be consulted prior to a final decision or action.

- Informed (I): Individual(s) who need to be informed after a decision or action is taken.

- Tester (T): Individual(s) testing the project, if everything is done right

Table 5 displays the RACI matrix for this project.

<WRAP centeralign>

</WRAP>

<WRAP box center centeralign 900px>

| Delivery | Anna | Jan | José | Margot | Raymond | Coordinator | Teacher | Supervisors |

|---|---|---|---|---|---|---|---|---|

| Gantt Chart | R | A | I | I | I | |||

| System diagrams | A | R | A | I | I | C | ||

| Structural drafts | R | A | I | I | C | |||

| System schematics | R | A | I | I | C | |||

| Structural drawings | R | A | I | I | C | |||

| Cardboard scale model | A | R | I | I | I | |||

| List of materials | A | R | I | I | C | |||

| Interim report | A | R | I | I | I | |||

| Interim presentation | R | A | I | I | I | |||

| Structural building | A | R | R | I | I | C | ||

| Software building | R | A | A | I | I | C | ||

| Testing and performance | T | R/T | T | T | T | I | I | C |

| Video | A | R | I | I | I | |||

| Paper | R | A | I | I | I | |||

| Poster | A | R | I | I | I | |||

| Manual | R | A | I | I | I | |||

| Leaflet | A | R | I | I | I | |||

| Final report | R | A | A | A | A | I | I | I |

| Final presentation | A | A | A | R | A | I | I | I |

</WRAP>

- Acquire project Team: Processes of obtaining the human resources needed for completing the project.

Due to the high number of participants in this project, the ISEP management Team was responsible for selecting team members. For this, three factors were considered:

- Nationality.

- The field of specialty.

- The role of each member.

To determine this last one, The test called Belbin team roles was performed. This test goal is to bring the right people together, so that the teams are more likely to succeed and achieve their goals [42]. In total, there are nine different team roles, which descriptions is shown in Fig. 16.

<WRAP centeralign>

</WRAP>

Table 6 displays the results for each member of this group.

<WRAP centeralign>

</WRAP>

<WRAP box center centeralign 450px>

| Team member | Team role assigned | |

|---|---|---|

| Anna | Shaper | Team Worker |

| Jan | Plant | Team Worker |

| José | Completer finisher | |

| Margot | Plant | Team Worker |

| Raymond | Completer finisher | Team Worker |

</WRAP>

- Team development: This includes both enhancing the ability of stakeholders to contribute as individuals as well as enhancing the ability of the Team to function as a team. In order to enhance and promote this team development, different activities are carried out:

- Team-building activities: During the first two weeks of the project, different team-building activities were done, such as trust games, a mascot's building, etc. They were carried out to promote the members to know each order and gain confidence.

- Weekly supervisor's meeting: Every thursday, a meeting with the EPS supervisors is scheduled. Thereby, different concerns about project development and teamwork can be consulted.

3.7 Communications

The main objective of communication management is to ensure that the communication between two people or a group goes smoothly [44].

The difficulty in the group is that every team member speaks another native language and everyone was raised in slightly different cultures. Also, the team members did not know each other before the beginning of the project, they have therefore never worked together and so do not know the others strengths or weaknesses. A third problem or maybe an advantage can be that they have different backgrounds of education, so they might know a lot about some subjects but also some subjects can be totally new for them, when other team members take it for granted.

Taken these flaws and strengths into account, it is important the team members meet at a regularly base. Besides:

- The team members see each other every weekday at school and work at their part of the project.

- If they need help, they can always ask another team member to help them.

- They use a group conversation on WhatsApp to arrange those meetings.

- For bigger discussion there is also a group made on Facebook to help them.

- The sharing of necessary documents is done through Google Drive, a file storage and synchronization service developed by Google.

If the problem cannot be solved within the group, the team members can always turn to their coordinator, Fernando Ferreira, this can be done by mail. Furthermore there are also weekly meetings between the team members and all the supervisors of the EPS program. All questions can be asked here and also the project will be evaluated.

The things the Team needs to communicate, from tho whom, are shown in Table 7.

<WRAP centeralign>

</WRAP>

<WRAP box center centeralign>

| What? | Why? | Who? | When? | To whom? |

|---|---|---|---|---|

| Deliverables | Achieve the goal of the project | The team members | On the deadlines | The supervisors, teachers and the other team members |

| Team meetings | Plan how to deliver the deliverables | The team members | Few times a week | The team members |

| Meeting with coordinator | Get feedback on the project | The team members and the coordinator, Fernando Ferreira | Every two/three weeks | the team members and the coordinator |

| Meeting with supervisors | Get feedback on the project and discuss our ideas | The team members and the supervisors | Every Thursday morning | The team members and the supervisors |

</WRAP>

3.8 Risk

Table 8 shows some of the risks to the project's success. The team has discussed each risk and the action to be taken should one of the risks occur. The risks are ranked by assessing the impact on the project as well as the probability of the risk occurring.

<WRAP centeralign>

</WRAP>

<WRAP box center centeralign 200|400|400px>

| Description | Cause | Effect | Trigger | Response | Impact | Probability | Rank |

|---|---|---|---|---|---|---|---|

| Materials - Late/Unavailable | Supplier/Bureaucracy | Delay in Work Commencing | Information from Supplier/ISEP | Provide List of Materials Early | High | High | 1 |

| Design Error | Lack of Knowledge/Human Error | Product may not Work | Noticing the Error | Repair Error/Find Alternative Solution | High | Medium | 2 |

| Manufacturing error | Lack of Knowledge/Human Error | Product may not Work | Noticing the Error | Repair Error/Find Alternative Solution | High | Medium | 2 |

| Bugs in Software | Human Error | Product may Work Improperly | Noticing the Bug | Test Code Frequently/Correct the Bug | Low | Medium | 5 |

| Going Overbudget | Delivery Costs/Unexpected Costs/Poor Budgeting | Being Unable to Purchase all Required Materials/ Justification of Additional Costs | Having Spent a lot of Money | Minimising Costs/Contingency Fund/Presenting Justification for Additional Costs | High | Medium | 2 |

| Missing Deadlines | Poor Project Management/Unforseen Circumstances | Project Failure | Not Having the Work Done Close to the Deadline | Monitoring Deadlines/Setting our own Earlier Deadlines | High | Medium | 2 |

| Illness | Bacteria/Virus | Reduction in Working Hours | Beginning to Feel Ill | Living Healthily/Visiting a Doctor | Medium | Medium | 3 |

| Lateness | Public Transport/Other | Delay in Work Commencing | Looking at Watch/Travel Updates | Updating the Team | Low | High | 4 |

| Resources - Lab Unavailability/Tool Failure | Scheduling/Maintenance | Rescheduling Required | Information from ISEP | Good Organisation/Alternative use of Time | Medium | Low | 5 |

</WRAP>

3.9 Procurement

Procurement is the act of obtaining or buying goods or services. It contains also the management of this process, so the preparation and the processing of these goods and services [45].

In this project there is a budget of 100.00 €, the main goal is to stay under it. Regarding the actions that can be carried out for this purpose, are:

- Look at the different suppliers and at their quality-price ratio.

- Try to work as much as possible with the materials that are already at their disposal.

- Communicate with the other EPS teams, see witch materials they need. Often it is cheaper to buy materials in large quantities, if they work together well and chose for the same materials, it could have an effect on the final price.

- To reduce costs there will be mainly looked at the local suppliers; this is done to minimalize the shipping costs.

3.10 Stakeholders management

Within stakeholders’ management, the team members are going to try to analyse, plan and execute the actions to engage with stakeholders [46].

First of all it is necessary have to identify the stakeholders. Stakeholders are individuals or companies that are interested in this project, they are directly or indirectly involved in this project. Second of all their interests and influences are going to be assessed. Departing from this a communication management plan has to be developed (see section 3.7). At last it is the intention to engage and influence the stakeholders.

Table 9 shown the stakeholders for this project.

<WRAP centeralign>

</WRAP>

<WRAP box center centeralign 200|400|400px>

| Stakeholders | Role | Expectation | Power | Interest |

|---|---|---|---|---|

| Team Members | Execute the project | Develop the project, expand knowledge | High | High |

| Team Supervisor | Supervise the project | Help succeeding the project | High | High |

| EPS coordinators | Evaluating project and helping | Help succeeding the project | High | High |

| Teachers | Expand the team members knowledge and evaluate project | Help succeeding the project and expanding our knowledge | High | High |

| Suppliers | Providing materials | Selling materials | High | Low |

| ISEP | Sponsor | Developing interesting projects | High | Low |

</WRAP>

3.11 Conclusion

As can be seen, project management not only focuses on time control as long as the project is completed within the established time frame. In addition, it is important to:

- Define accurately the resources, whether human or material, necessary to carry out the project.

- To carry out an exhaustive control of the expenses that derive from the project, in order to avoid concurring in unnecessary expenses.

- Have well defined the quality requirements that the product must meet.

- Identify all those situations that pose a risk to the successful completion of the project.

Taking into account all these aspects, and implementing the tools available for this, it can be ensured that the project can be carried out with the maximum rigor and minimum risks.

4. Marketing Plan

4.1 Introduction

Many organisations are becoming more and more customer-centric. For most marketing teams the experiences of the customers are a priority. The goal of marketing is to improve the performance of an organisation by responding to the needs of these customers or let the customers think they need the things that the organisation is selling. In this chapter the marketing plan for the Self-Oriented Solar Mirror (SOSM) can be found. The marketing plan consists of a Market analysis including the micro- and macro-environment; a Strengths, Weaknesses, Opportunities And Threats (SWOT) analysis; the Strategic objectives including the Specific, Measurable, Attainable, Relevant and Time based (SMART) principal; Market Segmentations; Positioning strategy; Adapted Marketing-mix as an 4P model; a Budget and a Strategy control.

4.2 Market Analysis

Every business organisation is a part of the business environment, within which it operates. No entity can function in isolation because there are many factors that closely or distantly surround the business. It is broadly classified into two categories (see Fig. 17) [47]:

- Micro environment: Affects the working of a particular business only, to which they relate to, It has a direct impact on the business activities.

- Macro environment: Affects the functioning of all the business entities, operating in the economy. Is a general business environment, which influences all business groups.

<WRAP centeralign>

</WRAP>

4.2.1 Micro environment

Micro environment refers to the environment which is in direct contact with the business organization and can affect the business straight away [48]. It is a collection of all the forces that are close to the firm. They can influence the performance and day to day operations of the company, but for a short term only. Its elements include suppliers, competitors, intermediaries, customers and publics. The firm itself is an aggregate of a number of elements like owners, shareholders or investors, employees and the board of directors.

Suppliers

Suppliers are defined as the ones who provide inputs to the business like raw material, equipment and so on. These can control the success of a business when they hold the power. For example if some materials are needed and there is only one supplier for the specific material [49].

The SOSM contains a lot of electrical components like a real time clock, controller, a stepper motor, power supply and also building materials. All of these products can be bought here in Portugal. To choose the providers more research have to be done.

Competitors

Competitors are defined as the rivals, which compete with the firm in the market and resources. The competitors are those who sell the same or similar products and services as SUNO, and the way they sell their product needs to be taken into account. New ideas have to be invented to have to get ahead of SUNO's competitors [50].

One of the competitors of SUNO is “Wikoda” which provide sunflowers to get more light into a home. This sunflower however is more expensive than SUNO's product. Our product provide the costumer a more natural lightning than the lightning industry.

Intermediaries

Marketing intermediaries may include wholesalers, distributors, and retailers are defined as those that make a link between the firm and the customers [51]. SUNO would be mainly sold business to consumer (B2C) but can also be sold business to business (B2B). Costumers and businesses can buy the SOSM immediately from SUNO's website.

Customers

Customers / Consumers are defined as the ones who purchase the goods for their own consumption. They are considered as the king of business. The customers depends if the business relations are Business-to-Business (B2B) or Business to Consumer (B2C) and what their reasons for buying the product are. Depending on the business relation and the reason, the approach at marketing has to be changed [52].

SUNO's costumers like already told will be mainly consumers but also businesses. Consumers will use it for home use in their gardens or on their terras probably to light up a room. Businesses on the other hand will probably use for winning energy in their manufactory, but can also use it for lighting in the offices.

Publics

SUNO has a duty to satisfy the public and all the actions must be considered from the angle of the public and how they are affected. The public can either help reach the goals or prevent the company from achieving them [53]. The SOSM is presented as a green product, it is a way to create green energy by using the sun. Therefore, SUNO is making sure that the manufacturing and materials that are used are eco-friendly.

4.2.2 Macro environment

The definition of a Macro environment is the environment within the economy that influences the working, performance, decision-making and strategy of all business groups at the same time. It constitutes forces that are not under the control of the company but have a powerful impact on it. The study of Macro environment is known as Political, Economic, Social, Technological, Legal and Environmental (PESTLE) Analysis [54] [55].

Political/ Legal

The political and legal factor depends on the stability of the political environment and the attitudes of political parties or movements, government influence on tax policies or involvement in trading agreements. The political factors go hand in hand with the legal factors such as national employment laws, international trade regulations and restrictions, monopolies and mergers´rules, and consumer protection. The difference between these two are that the political factors refers to attitudes and approaches whereas the legal factors are those which have become law and regulations and needs to be complied [56].

Many political parties support the production of green energy. The clean energy industry generates hundreds of billions in economic activity, and is expected to continue to grow rapidly in the coming years. There is tremendous economic opportunity for the countries that invent, manufacture and export clean energy technologies. [57]

Economic factors

The economic environment can impact both the organisation’s production and the consumer’s decision-making process. It varies from one country to another. For the SOSM these economic factors may include economic growth rates, levels of employment and unemployment, costs of raw materials such as energy, petrol and steel, interest rates and monetary policies, exchange rates and inflation rates [58] [59].

The SOSM is also presented as a way to lower the energy bill. Therefore the SOSM should cost less than the costs of the energy that the consumer wins by using the SOSM. To make sure this happens, the SOSM should be sustainable, it has to have a long timespan and also shouldn't be too expensive.

Social

How a company's product impact the society must be considered, any elements that are harmful to society should be eliminated to show that the company is taking social responsibility. But the social factors also represent the culture of the society, that may include demographics, age distribution, population growth rates, level of education, distribution of wealth and social classes, living conditions and lifestyle [60] [61]. But also social media is becoming more and more important these days.

SUNO will use social media as main way to introduce the SOSM on the market. First of all a website will be made, this will be distributed by social media like Facebook, google, etc.. Next SUNO will place advertisements in newspapers, but also distribute flyers at local electronic stores and hang up posters there. Other social trends, like living eco-friendly and helping the environment will also help sell the SOSM.

Technological factors

Skills and knowledge have to be considered to the production and the technology such as new inventions and development, changes in information and mobile technology changes in Internet and e-commerce or even mobile commerce, and government spending on research. The technological environment should also include materials needed for production of products and services, materials development and new methods of manufacture, distribution and logistics [62] [63].

The technological factor is focused on the change in the use of technology. The solar mirror that SUNO is going to provide is self-oriented, so orientation will be automatically after the device is set up. SUNO will also keep in ind how they can in the future improve there product and keep up with the newest technologies.

Environmental

Country, age, ethnicity, education level, culture and so on have a huge impact on the environmental issues but also the Earth’s renewal of its natural resources and the natural non-renewable resources. It can also include issues such as limited natural resources, waste disposal and recycling procedures [64] [65].

The SOSM will use only recyclable materials and will optimize the reuse of the different parts of the product. The customer can always contact the company if something is not working. If one of the parts breaks, the customer can always buy new parts and even get a discount when they turn the old ones in. That way SUNO avoids having to replace the entire product and is making sure that the old parts are used in a proper way. SUNO can choose to make the broken parts or recycle them properly.

4.3 SWOT Analysis

SWOT analysis is an enterprise financial planning tool which attempts to find strengths, weaknesses, opportunities and threats in a strategic review. SWOT analysis maps the external and internal factors relating to the situation being analysed and whether or not the properties are good or harmful (see Fig. 18).

Strengths: All of us have different knowledge and personalities and we all have different skills so we can help each other. We also have a panel of supervisors that provide us with feedback and help.

Weaknesses: We all have different personalities which can make it harder to cooperate, even harder when we don't speak the same language. The language difficulties can also make it hard to communicate and mistakes also happens easier. Our lack of knowledge can of course be a big problem.

Opportunities: Nowadays people are more aware of the environmental problems and wants to be more sustainable, it is very popular to think ecological.

Threats: There are already some products on the market, so we need to make our product special from our competitors 4.2.1. We didn't have a clear purpose of the project which makes it harder to find a market group and of course the limited budget of 100.00 € makes it harder.

<WRAP centeralign>

</WRAP>

4.4 Strategic Objectives

When starting a company, it is first of all very important to know where the company is headed to, to have a goal. These goals are mostly based on the SMART principal, the goal has to be Specific, Measurable, Attainable, Relevant and Time based [66].

For SUNO, next goals could be taken:

- Build a fully-functional self-oriented solar mirror.

- Make a website.

- Develop and use a customer database.

- Find cheaper and more sustainable resources.

- Ameliorate the solar mirror: make it more robust and more effective.

- Introduce the product outside of Europe.

4.5 Segmentation

To get a clear image of the market of this project, the market is going to be divided into segments, these are homogenous groups. There are four market segmentation bases, the geographic, demographic, psychographic and behavioural segment. Each of those segments have to conclude the points that are shown in Fig. 19.

<WRAP centeralign>

</WRAP>

- Geographic Segmentation: Because SUNO is just starting, the geographic market target will be Portugal. After it grows bigger, SUNO could start expanding first to Spain, then to the rest of Europe and even outside. As it provides more solar energy, there are no countries where SUNO could not expand too. Third world countries could use it easily to cook or heat water, Probably charity organisations will be here the main target those countries.

- Demographic Segmentation: For the demographic segmentation, the target group will be people who are getting out of their parents house and they are maybe starting with a family of their own. Also people who have already their homes for a long time and that are looking for a greener lifestyle or also just searching to safe money. People with low income will probably not be able to buy it. The SOSM has as goal to provide more energy for people that already have solar sells, so people with lower income will probably try to lower their energy consumption before buying this product. So the market target will have the next characteristics:

- Age: 30-70.

- Income: medium to high.

- Education: higher educated persons.

- Religion/Nationality: All.

- Psychographic Segmentation: For the psychographic segmentation, the main target is people who care about the environment, but also people who want to save money on energy. So people with a green or economical lifestyle will be the main target. A higher social class, so people who have had a better education and have higher income, like already said in the demographic segmentation, will be more likely buying this product.

- Behavioural Segmentation: As last, there is the behavioural segmentation, how people behaviour will influence buying this product. The SOSM is an expensive device and not much people will buy it out of impulse. They will probably discuss it before buying it with their partner.

4.6 Strategy/Positioning

There are three steps (see Fig. 20) that have to be considered when choosing a positioning strategy [67]:

<WRAP centeralign>

</WRAP>

SUNO have a few different competitors, companies that are producing solar mirrors and companies that are making lighting devices. Compared to the competitors on solar mirrors SUNO is going to focus on making the product cheaper but also on making it for a more general purpose. Looking at the lightning industry, SUNO will propose this product as a product that saves energy. In the long-term, the product will pay for itself.

The perceptual map (see Fig. 21) shows the connection between the price and the purpose of the product, specific or general. When we bring our product to the market it is important to know where we stand regarding these two values. All of the existing products that we have compared to have a more specific purpose and regarding price our product is cheaper compared to Wikoda (sunflower) but more expensive than the lighting devices.

<WRAP centeralign>

</WRAP>

SUNO has some options on places where it can sell his product, one of them is online and there is also where the competitors on the SOSM are selling their product, but it can also been sold in electronic stores or garden stores.

4.7 Adapted Marketing-Mix

In Fig. 22an adapted marketing mix for SUNO can be seen, a 4P model: Product, Price, Promotion and Place. The model is used to show SUNO's positioning in the market. <WRAP centeralign>

</WRAP>

Newt the 4P's will be discussed comprehensively.

4.7.1 Product

<WRAP centeralign>

</WRAP>

The product is a SOSM, and it the company and also the product is called SUNO (Fig. 23), which means Sun on Esperanto. The SOSM will help to get a more ecological and cheaper heating/ lighting so de customer can save both energy and unnecessary costs. The product can be used in the garden to light up a room or save energy by putting it on a solar panel.

The solar mirror is a simple way to harness solar energy and to transform it into energy that can be used daily. Raw materials are overused and new sources of energy are needed. The goal of this project was to develop a Self-Oriented Solar Mirror (SOSM). The mirror must track the movement of the Sun and reflect the sunlight onto a predefined area. Without a defined purpose for the mirror it was initially difficult to know the target market and how to proceed with the project. The creation of the sun tracking system was one of the main challenges for SUNO. The SOSM had to detect the Sun by itself with the aid of sensors or with software that knows the path of the Sun. The consumer will need to do a setup in the beginning defining where the mirror should be focused.

There are already some solar mirrors established in the market, nevertheless most of them are very expensive, and SUNO is going to ensure to make the product cheaper.

4.7.2 Price

Before SUNO sets a price on our product the Team need to check prices on existing market and compare them. SUNO can see that similar products cost around 275.00 €, and this product will cost around 200.00 €, but it is necessary to be careful because the product is very customer price sensitive, if the price is too low people may have concerns about the quality.

The product will pay for itself and it will provide long-term savings on energy. The costumer should be able to pay the product with PayPal, debit/ credit card etc.

4.7.3 Place

Before SUNO begin the selling, SUNO has to think about to whom they want to sell their product, there were two main options, business to business (B2B) or business to consumer (B2C). If SUNO decides to sell their product directly to the consumers their main business market will be online on their own website, and there is where the costumers will look for their product. SUNO could also decide to sell the SOSM directly to a business for example an electronic store or a garden store.

SUNO can have a good use of a sales force of people that knows the language and that have the right contacts that can help them to access the right distribution channels.

4.7.4 Promotion

The cheapest way for SUNO to promote their product is on social media, like Facebook and Instagram, but social media is also good way to reach customers at all ages. Another good way to reach customers is by handing out flyers. The competitors if SUNO have only promoted their product on social media.

The best time for SUNO to start promoting their product would be around March. This is because the sun is coming out more and more and people will think more of applying solar energy. But also in the winter it will not be bad to promote our product as people will also look for solutions to get more heat into their homes.

4.8 Budget

It is important to set a budget on the side for marketing. People have to know that our product exists. SUNO has a budget of 5000.00 €, and want to put the most of this in online advertising. SUNO has to have a good website, that appeals to the persons, for this a budget of 1200.00 € is foreseen. The link to this website, SUNO wants to share on Google and Facebook. At social events SUNO wants to hang posters and distribute leaflets to people. The budget allocation is shown in Table 10.

<WRAP center centeralign 400px>

| Action | Budget |

|---|---|

| Website | 1200.00 € |

| Advertisements on Google | 1000.00 € |

| Advertisement on Facebook | 1000.00 € |

| Advertising in Newspapers | 800.00 € |

| Poster | 500.00 € |

| Leaflets | 500.00 € |

| Total | 5000.00 € |

</WRAP>

4.9 Strategy Control

When executing a marketing plan it is important to have a controlling unit. Marketing control is the process of monitoring the marketing plan and adjusting them where necessary. If the marketing plan is being adjusted, an investigation has to be done to establish why this difference occurred. To perform a marketing control the steps in Fig. 24 have to be taken [68].

<WRAP centeralign>

</WRAP>

4.10 Conclusion

SUNO have now explained the differences between micro and macro marketing and made a SWOT analysis where they set the company strengths, weaknesses, opportunities and threats. SUNO have set the SMART goals for their product and one of the goals is to decrease dispenses over the next 5 years by a certain percentage. SUNO have adapted an marketing mix, 4P model, where they explained the product, price, place and promotion of their company and our team have decided that the smartest way for them to promote their product is on social media.

5. Eco-efficiency Measures for Sustainability

5.1 Introduction

Life on earth will be wiped out eventually, but how long will it take. It is human's task to cherish nature and be economic with all the raw materials the earth provides us, but we have taken it too far. Over the past century global warming has increased by 0.60 °C, and an even bigger increase is predicted [69]. Interest in “Eco-efficiency measurements and Sustainability” are starting to grow. They will to create a world were we can meet the needs of the present without compromising the ability of the future [70].

There are three main goals in sustainability, called the “Triple P” or the “Triple Bottom-line”. The three P’s stand for:

- People, the social development, this contains the well-being, health, safety, freedom of choice, … of a person.

- Planet, the environmental development, the conservation of the world, energy, water, materials, …

- Profit, the economic development, this includes prosperity, the gain, affordability and honesty.

- Some add a forth P, Politics.

These 3 points are shown in Fig. 25.

<WRAP centeralign>

</WRAP>

5.2 Environmental

The environmental impact is maybe one of the most disputed factors in the society. This is probably one of the main reasons that when people think about sustainability, they immediately think in the environment. The environmental development, mentioned here, contains the right use of materials. The goal is, like already mentioned, to meet the needs of the people without harming the ability of the future. To make a product environmental sustainable, three things have to be done:

- The rate of intake of renewable resources should be lower than the rate of reproduction.

- The rate of pollution should be lower than the assimilative capacity that the environment (the ability of the environment to clean itself).

- The reduction of non-renewable resources requires a comparable development of renewable substitutes.

5.2.1 Choice of materials

When materials are being chosen, there has to be taken into account the environmental development. Materials have to be renewable at a certain rate; non-renewable resources have to be avoided at all time.

The materials that are going to be use are:

- Polyvinyl Chloride (PVC).

- Medium Density Fireboard (MDF).

- Steel.

- Aluminium.

- Pine tree.

PVC was considered for this project. PVC is a synthetic derived material derived from oil and salt, which are not really good substances for the environment. Actually people really should stop using oil for everything, our resources are getting extinct. PVC is also not really biodegradable, and recycling is not always easy because most of the time additives are added. Besides, a lot of hazardous organochlorine by-products are formed with the production of chlorine gas [71]. Although PVC has disadvantages his ecological footprint is far less than other substances like steel and glass used for the same application. Because PVC is made out of 57% of Chloride, which is derived of salt, of which we have plenty of. In this way PVC contributes to oil and gas savings, because a lot of materials depend entirely on oil and gas. See the graphics in Fig. 26 [72]. PVC has also a longer lifespan than most other plastics.

<WRAP centeralign>

</WRAP>

MDF is a wood panel product made up of wood fibers (mostly from a pine tree) that have been bound together by heat, pressure and resin binders. The binders are often made from formaldehyde, a known carcinogen. Although they recently found out that lignin (a naturally occurring substance found in plants) can be used as a binder), most companies still use formaldehyde. MDF is completely recyclable, although the recycling process is new and the recycling locations are not always close by [74].

Next, there has been chosen to use Steel. One of the major advantages of this one is that it can be used infinitely. Steel is a material that people use, not consume. It will never lose value, never lose its properties. Therefore steel is the most recycled material on earth. There could be said that the non-renewable resources used to produce steel are not totally lost, because this one can be used forever and should not be made again [75]. Although this may seem like an ecological solution, timber still stays the best solution. It is a renewable resource and it is bio-degredable. The carbon footprint of those two materials are shown in Fig. 27

<WRAP centeralign>

</WRAP>

The SOSM is also going to consist of aluminium. Aluminium has similar properties as steel, as it can be used and recycled infinitely. Aluminium has one problem too, when it is produced with virgin sources it has an enormous ecological footprint. Nevertheless, when recycled sources are used the impact is far less, like shown on Fig. 28.

<WRAP centeralign>

</WRAP>

As shown above, wood is far the most sustainable substitute. So it is going to be used for many structural parts. Because it is an electrical device and the device will be outside, so it must be robust against the weather changes, not everything can be made out of wood unfortunately. There will also be searched for PVC without any additives.

5.2.2 Pollution control

As there has to be worked with a little budget, it is not possible to work with solar cells, therefore is necessary to connect it to the mains. Though whether the SOSM can be manufactured on a larger scale, is possible to make it run on solar energy. Because the device will always follow the Sun, which will lead to a higher energy gain. Also when there is no Sun, the solar mirror has no use, this means that there will not be needed any energy storage. Also in the manufacturing it could be best to use as much as green energy as possible.

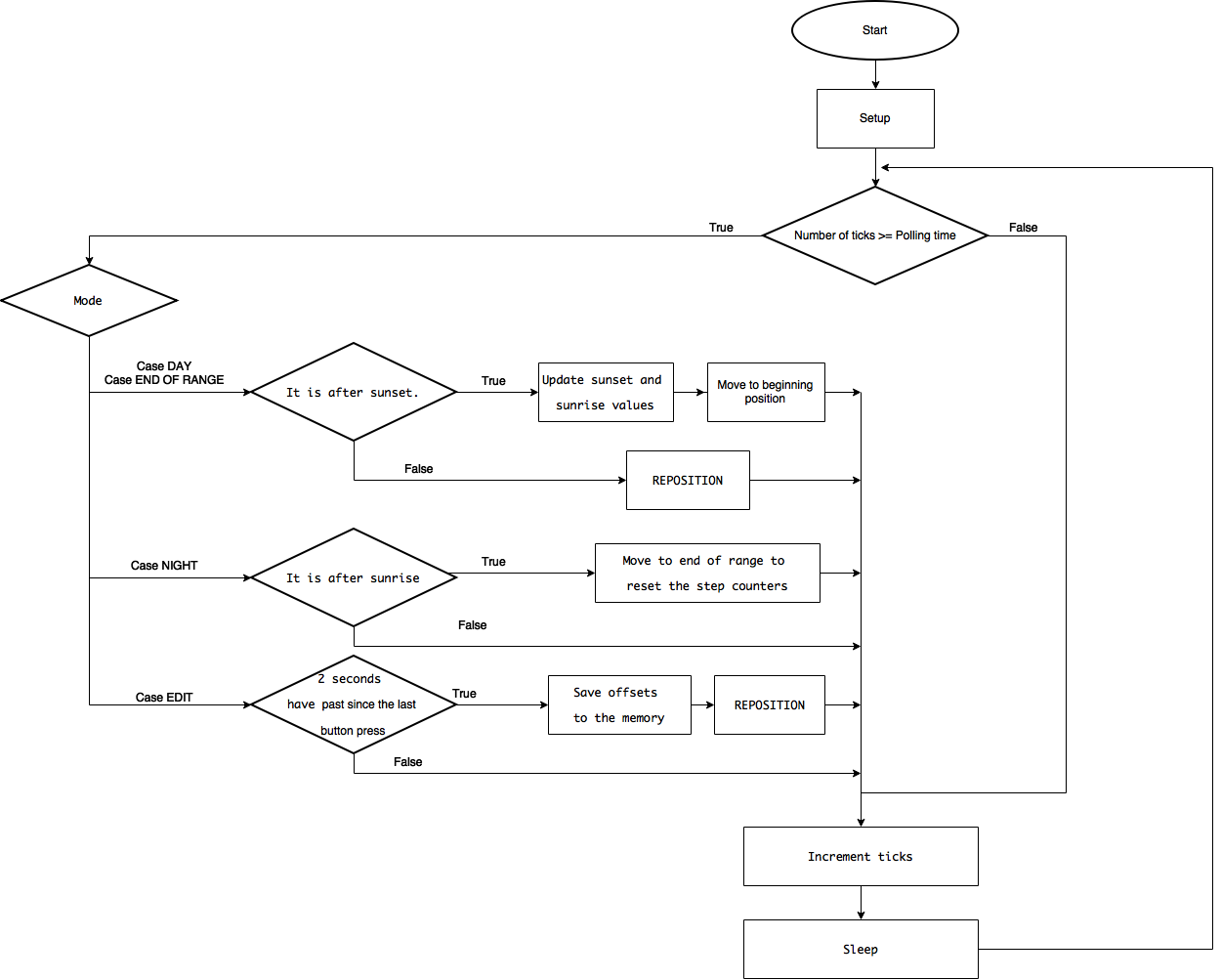

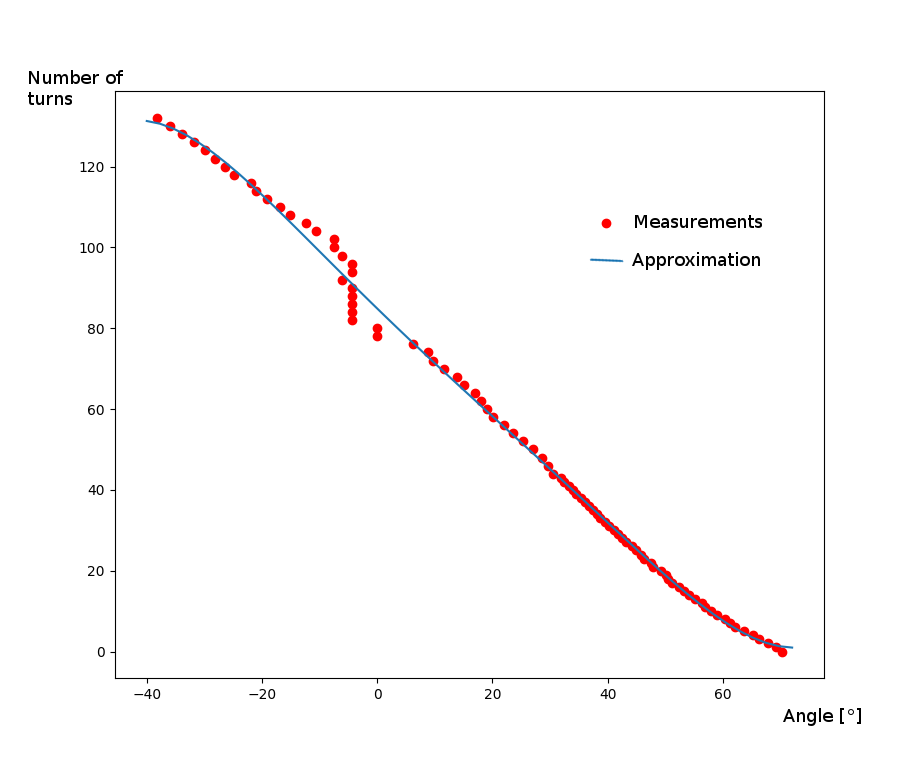

5.3 Economical